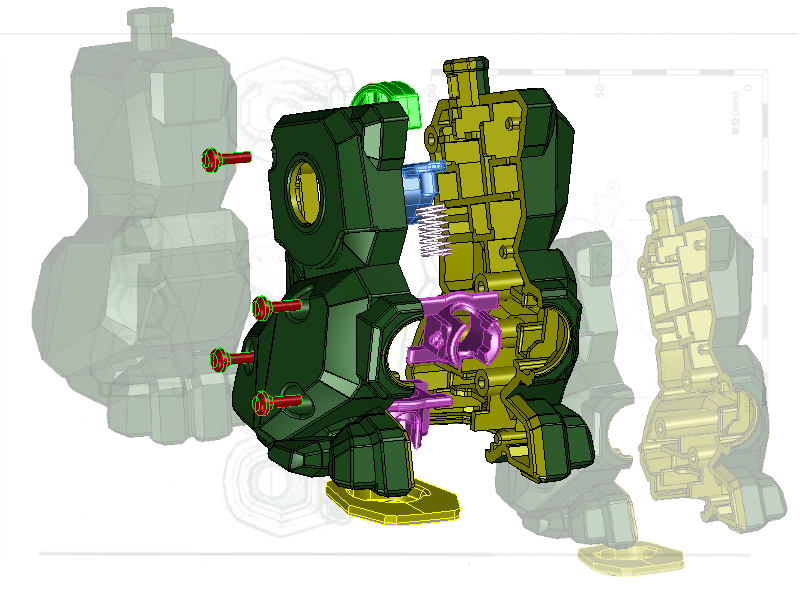

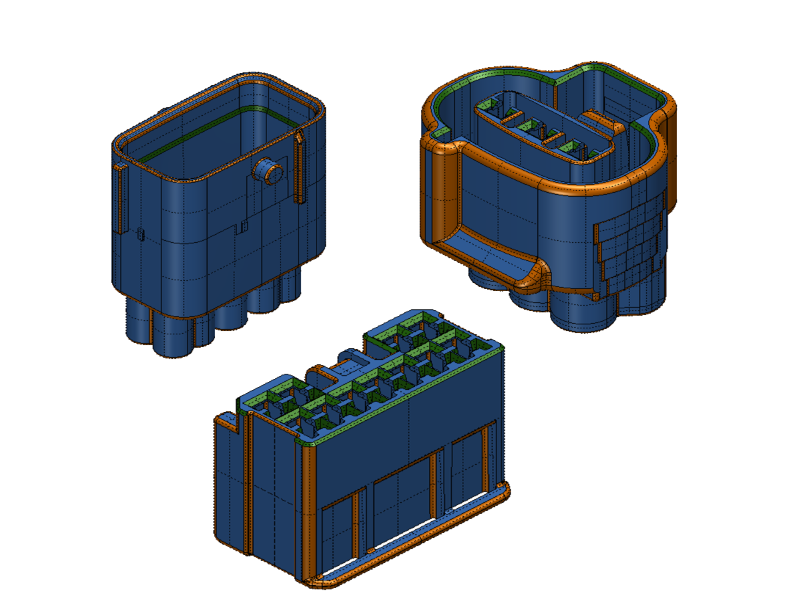

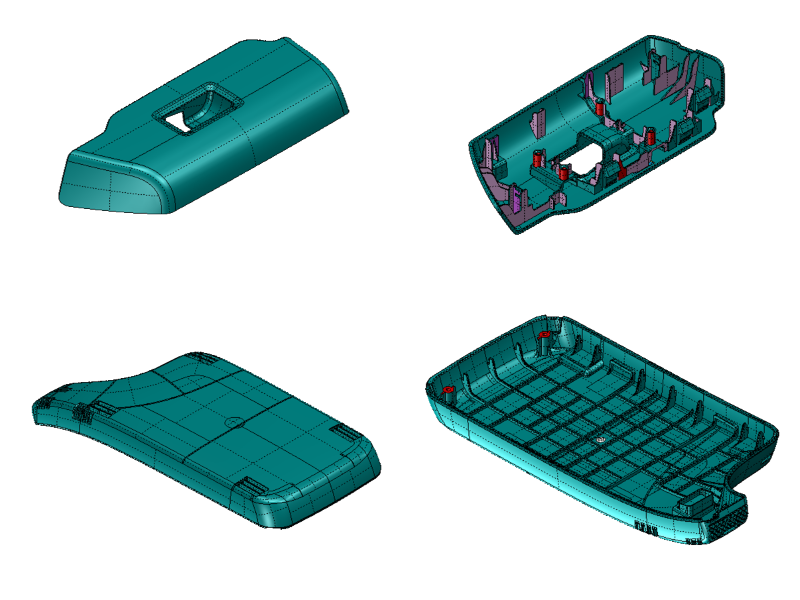

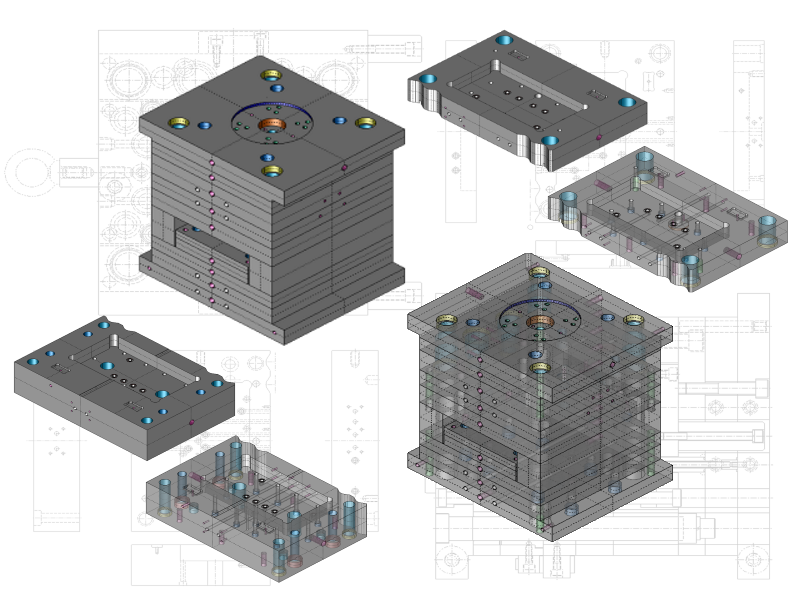

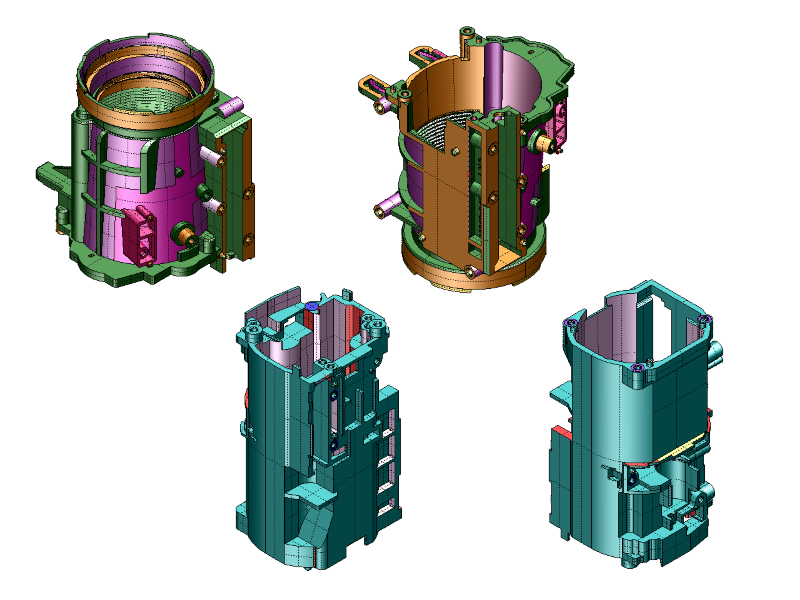

We deploy our skilled Design Engineers to create and evaluate 3D models based on your concept design to make sure that it can be feasible for molding process. After evaluation of the Concept design, we could make some suggestions that are based on the “MOLDABILITY” of the product. For the final delivery, we assure the quality of the Design has conformed and passed thru molding process standards.

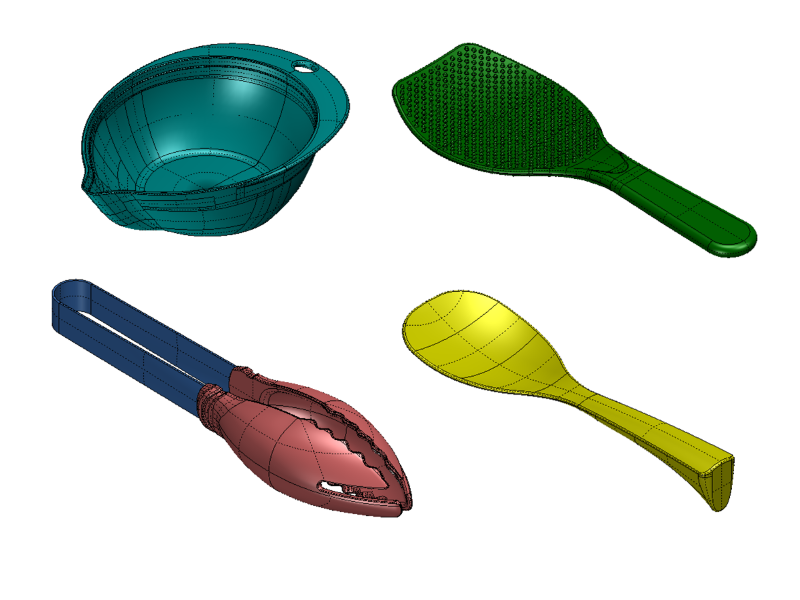

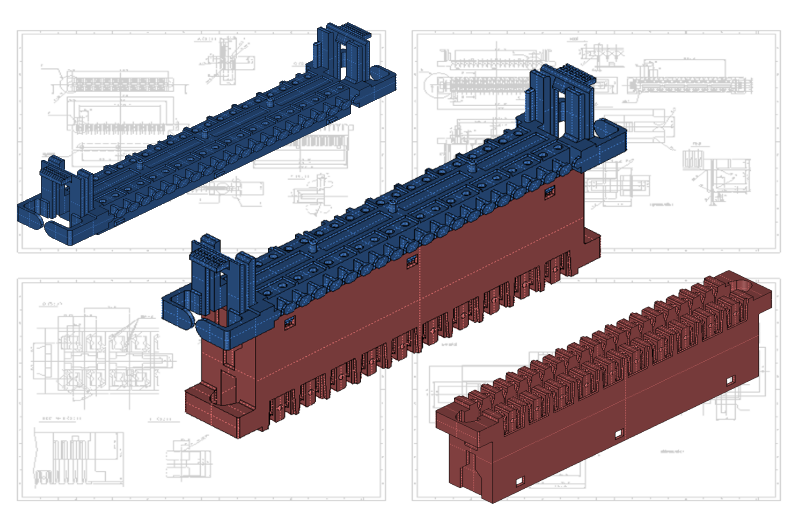

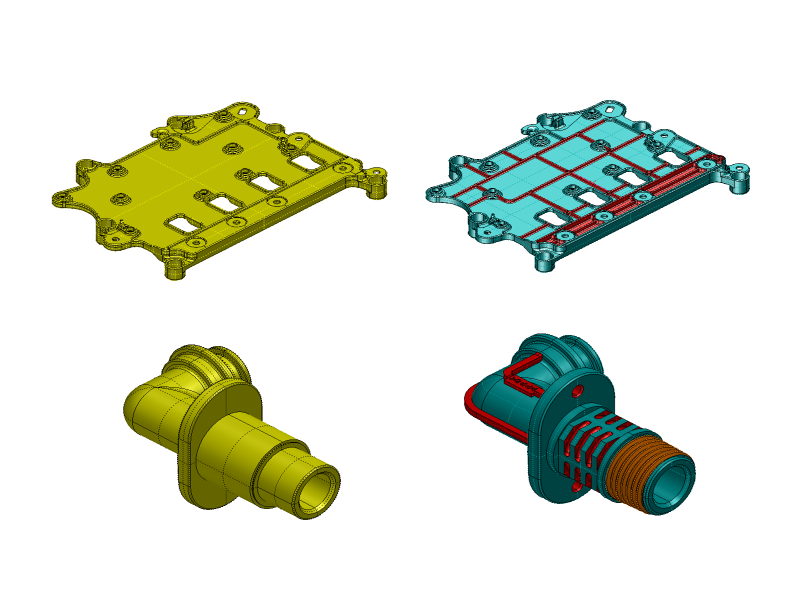

As 3D modeling is very important for every customer to imagine the concept design in a rendered environment, we can provide it by utilizing our state of the art 3D modeling software. We provide 3D Mechanical models in which any minimal design changes can be easily applied without such loss in our delivery time and without incurring additional cost for our customer.

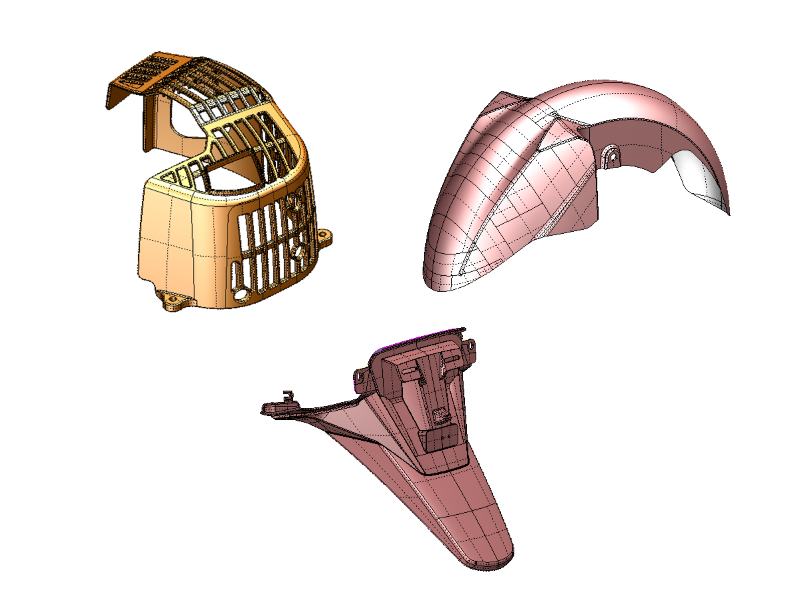

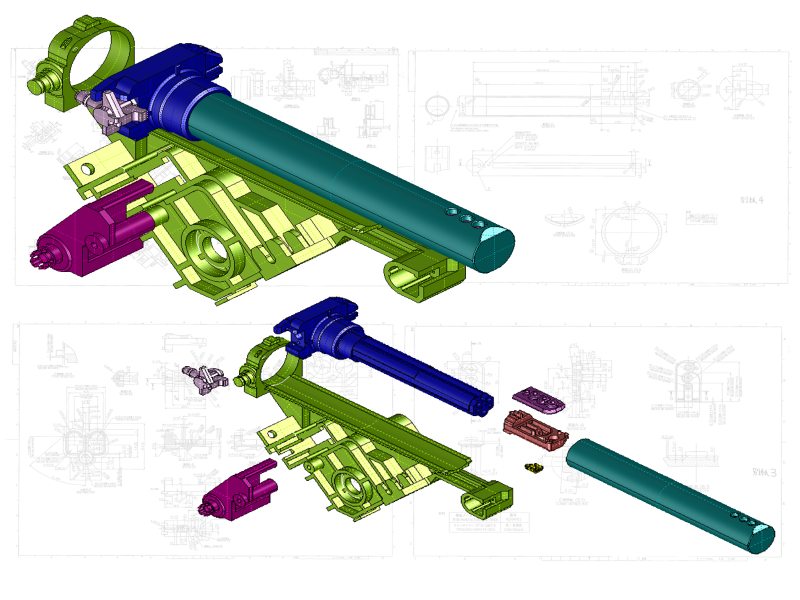

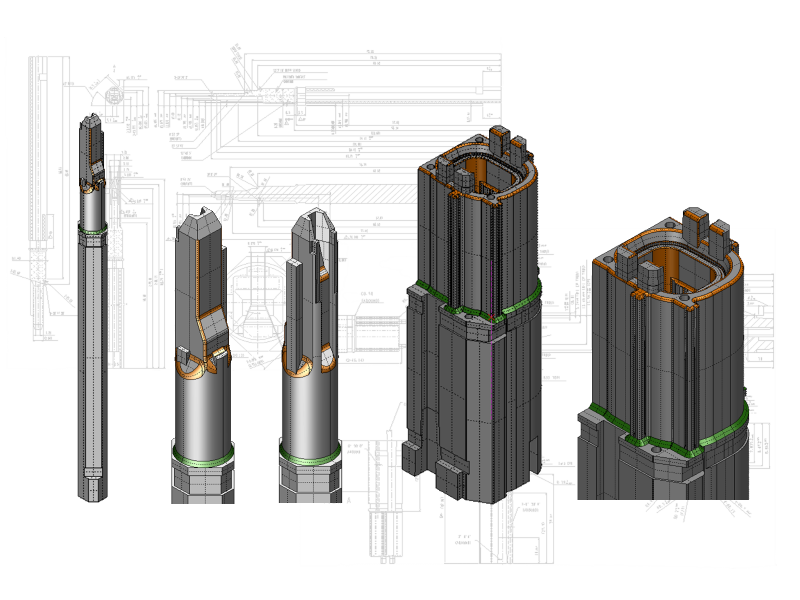

Based on our vast experience, we can create 3D models from Sketches, PDF and DXF data that are provided by our customers. Not only we could create 3D solid data from it but also Surfaces, Assemblies or Exploded 3D data. Our 3D modeling services are mostly utilize by Automotive, Motorcycle, Consumer Electronics Products, Manufacturing and Molding Industries (Plastic Injection, Die Cast, Blow and Press).

We can also modify any existing 3D model that are provided by our customer and to apply any design changes it wishes for. Our CAD system could translate CAD files such as IGES, STEP, Parasolid and Pro-E 3D data.

Product Modification is becoming an integral process in 3D modeling before initiating the Mold Design process. Not all 3D models can be called a “MOLDABLE” product. If not, we can immediately modify your 3D model to conform to your requirement or needs or to conform to the basic Molding standard.

During Product Modification, Our Design Engineers would be constantly looking for other ways to improve the design or inform your side if there are areas on the 3D model that was not covered of your initial requirement.

Email: info@ndedigitech.com.ph

Tel: (+632) 757 - 1025

Address: 3rd Floor Allegro Center, 2284 Chino Roces Ave., Makati City, Philippines