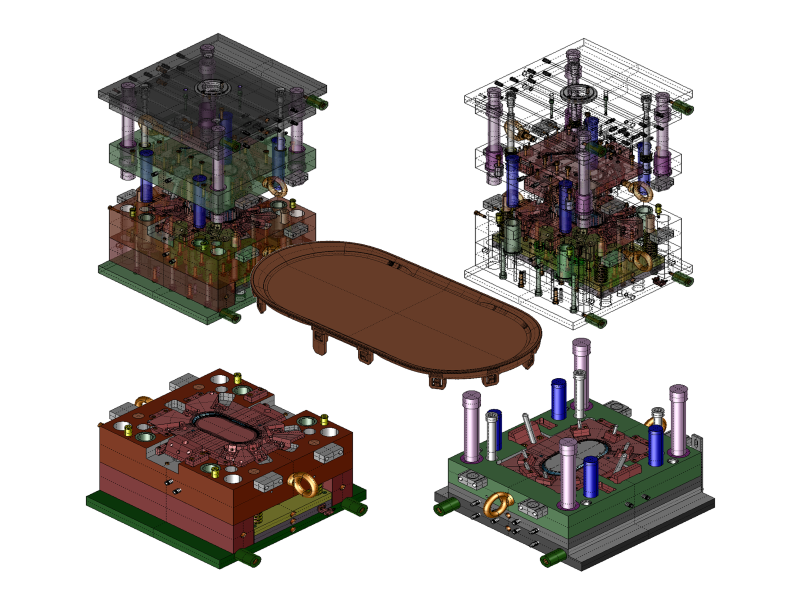

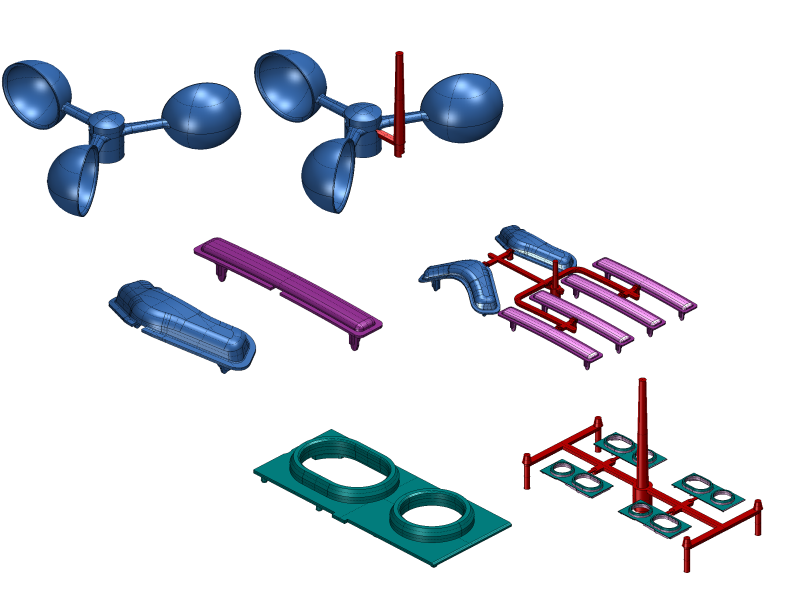

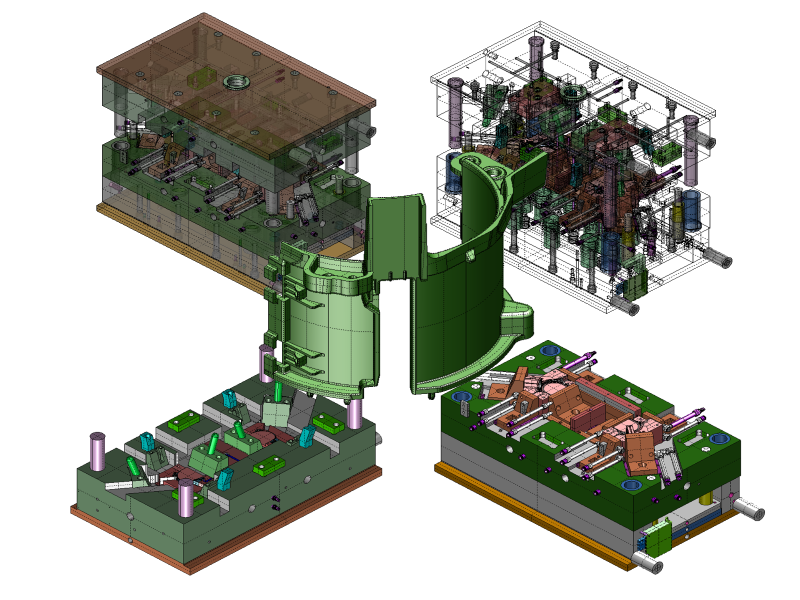

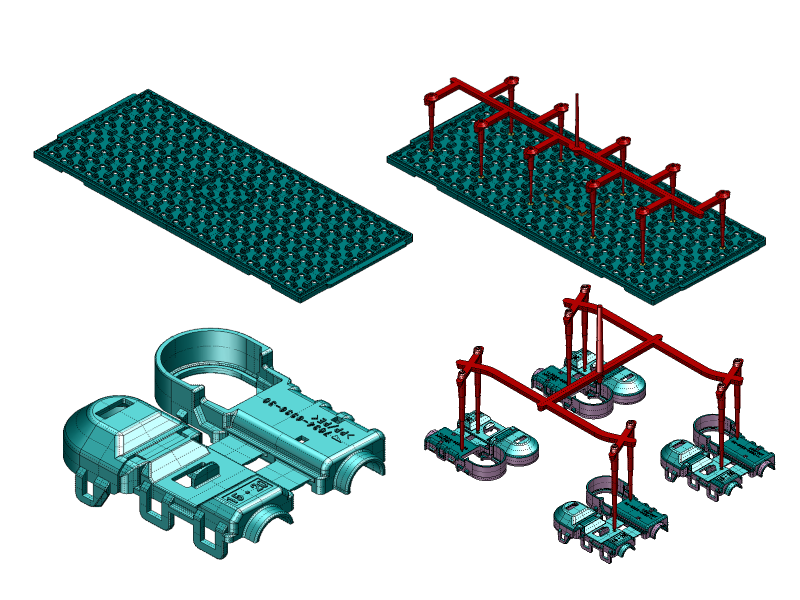

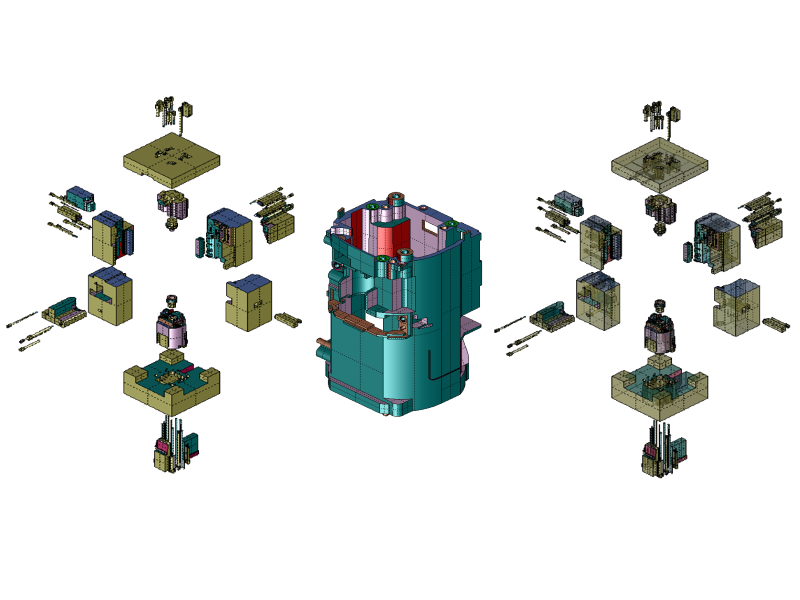

In Mold Design we always give our time and effort to design that would work properly and efficient. We design 3D models of a Cold-Runner Type Plastic Injection Mold (2-plate and 3-Plate) with complete parts and components for mass production.

Our design are based initially from Customer requirement and Specification, from it we gradually study and apply which standard Mold Base, Parts and Components to be use until the final design is complete. Our Mold Base design can adjust to plastic Injection machines varies from 15T up to 300T capacity.

Design content:

Other services:

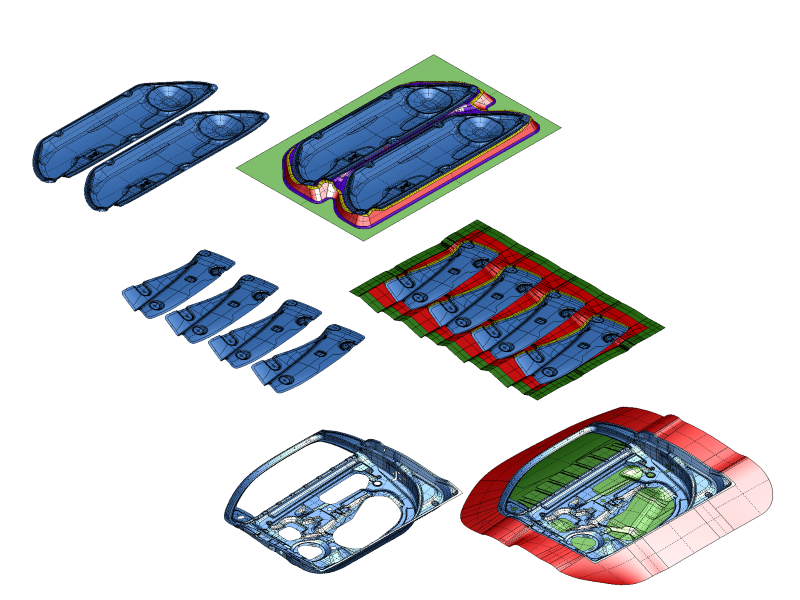

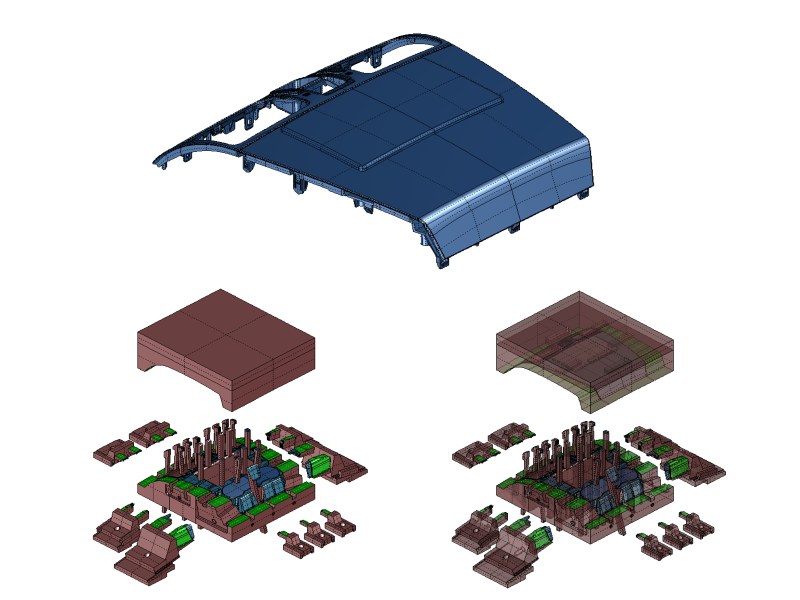

For Dieface Modeling, we create simple 3D surfaces that conforms to customer's standards and requirements. Our service is not only limited to sheet metal stamping but for Blow Mold Die designs as well.

Cavity and core insert are the main part of Mold base, which produce the plastic product. Our skilled engineers are designing cavity and core insert based on the customer requirements. We communicate with the customers to ensure proper wall and rib thickness, draft angle, gating layout are applied to the part based on proper specification and requirements. We also consider the capability of our customer to fabricate the inserts and assemble easily. And we assure the quality of our design by using our CAD system capabilty to check the draft distribution, undercuts and rate of shrinkage.

Email: info@ndedigitech.com.ph

Tel: (+632) 757 - 1025

Address: 3rd Floor Allegro Center, 2284 Chino Roces Ave., Makati City, Philippines